How to Cut Aluminum Composite Panel?

2025-11-03A Professional Guide to Cutting Aluminum Composite Panels (ACP): Tools, Techniques, and Best Practices

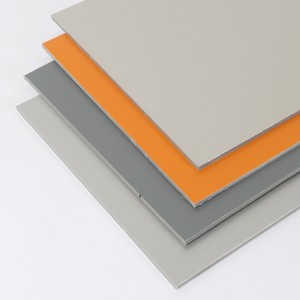

Cutting aluminum composite panel (ACP) is a fundamental yet critical process in fabrication and installation. Executing it with precision is paramount to achieving a flawless finish in architectural cladding, signage, and interior applications. An improper cut can lead to chipped edges, delamination, and visible seams, compromising both aesthetics and material integrity. This comprehensive guide details the professional methodologies for cutting aluminum composite material to achieve clean, factory-like edges consistently.

Section 1: Tool Selection - Matching the Tool to the Task

The choice of tool is dictated by the required cut (straight, curved, or complex) and the project's volume.

-

For Long, Straight Cuts: Circular Saw or Panel Saw

-

Circular Saw: The industry standard for on-site and workshop straight-line cutting. Equipped with a carbide-tipped blade with 80+ teeth designed for non-ferrous metals, it ensures speed and accuracy.

-

Panel Saw: Used in high-volume fabrication shops, it guarantees absolute precision and perfectly square edges with minimal operator error.

-

-

For Curves and Complex Shapes: Jigsaw

-

A jigsaw is indispensable for cutting arcs, circles, or custom shapes from ACP sheets. A fine-toothed, bi-metal blade (e.g., 24 TPI) for metal is crucial to minimize chipping on the top surface.

-

-

For Thin Gauges and Clean, Low-Dust Cuts: Utility Knife (Score-and-Snap)

-

For aluminum cladding panels up to 4mm in thickness, the score-and-snap method is highly effective. It produces a clean edge with no dust or noise, making it ideal for interior workspaces.

-

Section 2: Step-by-Step Professional Cutting Protocols

Protocol A: Cutting with a Circular Saw

-

Step 1: Marking & Support. Clearly mark the cut line on the protective film. Place the composite panel on a stable, fully supported workbench (e.g., sacrificial foam board or plywood). The panel must be firmly clamped along its entire length to prevent vibration.

-

Step 2: Blade and Saw Setup. Install a sharp, carbide-tipped blade. Set the blade depth to penetrate no more than 1/8 inch (3mm) beyond the material's thickness. This reduces friction and prevents chipping on the underside.

-

Step 3: Execution and Safety. Don safety glasses, hearing protection, and a dust mask. Guide the saw steadily along a clamped straight edge. Let the blade's teeth do the cutting; forcing the saw generates heat and melts the core.

-

Step 4: Post-Processing. After the cut, use a fine file or sanding block to deburr the sharp metal composite panel edge.

Protocol B: The Score-and-Snap Method

-

Step 1: Deep Scoring. Using a sharp utility knife and a metal straight edge, score the panel surface deeply and repeatedly (5-10 firm passes). You must cut completely through the top aluminum layer.

-

Step 2: Snapping the Core. Carefully lift the architectural panel on the scored line and bend it downwards in a swift, confident motion. The plastic core will snap cleanly along the score line.

-

Step 3: Severing the Back Skin. Fold the snapped portion back, and run the utility knife along the crease to cleanly cut through the remaining aluminum skin.

Section 3: Advanced Professional Tips for a Flawless Finish

-

Preserve the Protective Film: Always cut with the film intact. It is the first line of defense against scratches and tool marks.

-

Cut-Side Strategy: For circular saws, cut with the good side facing down as the blade's rotation enters from the top. For jigsaws, cut with the good side facing up.

-

Manage Heat Buildup: Excessive heat is the enemy of ACP. It melts the polyethylene core, causing it to gum up on the blade and potentially leading to delamination. Use sharp blades and a steady feed rate. For critical applications, consider using a blade with a non-stick coating.

-

Achieving the Perfect Inside Cutout: Drill a starter hole within the waste area large enough for your jigsaw blade. This allows you to make internal cuts without notching from the edge.

By rigorously applying these professional techniques and understanding the properties of the aluminum composite panel, fabricators and installers can ensure every cut meets the highest standards of quality and durability.